Air conditioning

Consistent sustainability to protect the climate and the environment

For our company, products and supply chains, sustainability is the central point around which we orientate our thinking and actions. To this end, we are constantly developing new measures, optimising processes and promoting projects. We continuously invest in renewable energies, energy-efficient machines and modern systems that serve to protect the climate and the environment.

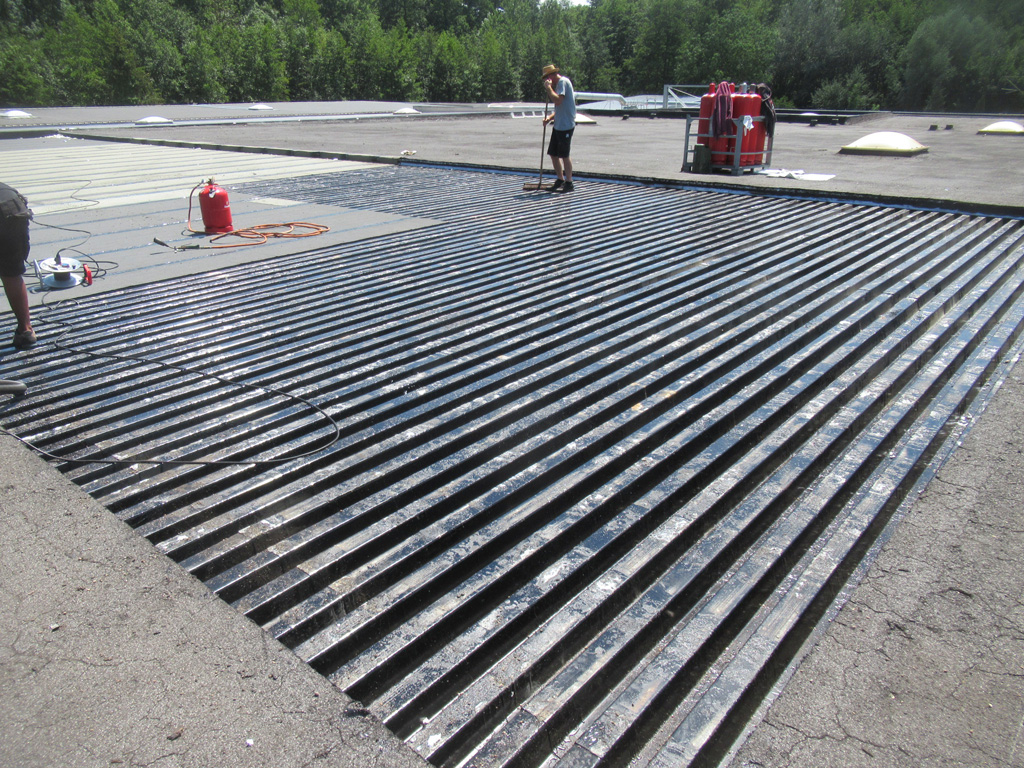

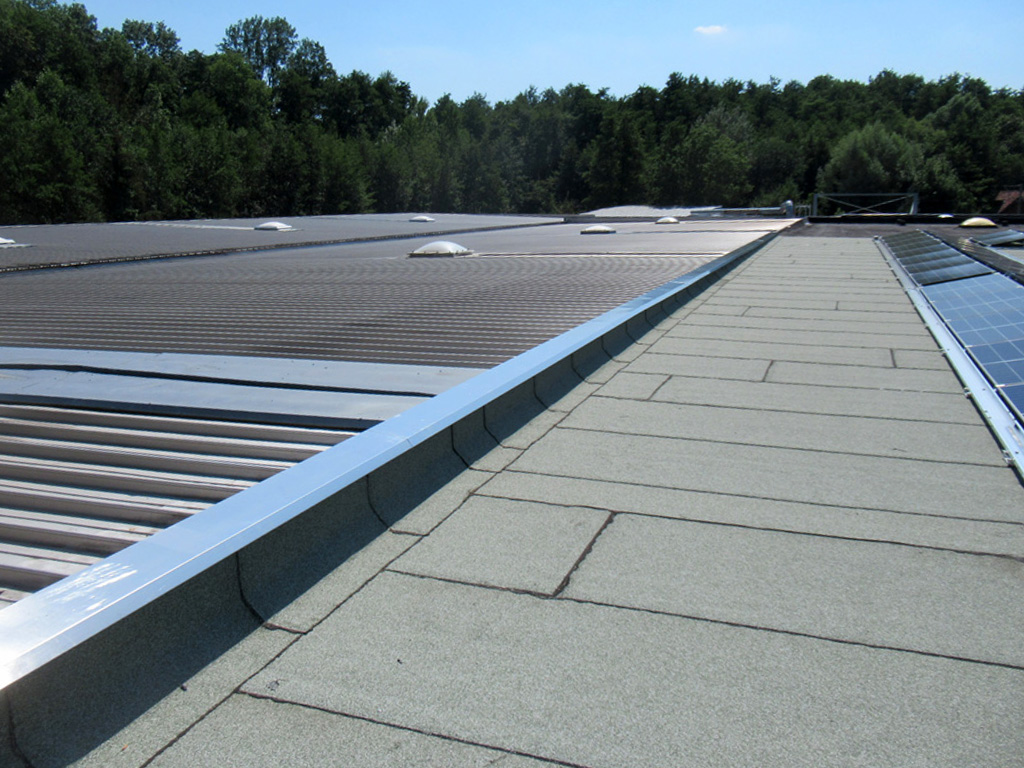

Use of renewable energies

On the way to becoming a CO2-neutral production site, a photovoltaic system was installed on the roof of our production facility, which is continuously being added to. It has a peak output of 165 kWp. It supplies us with climate-friendly and CO2-neutral electricity from solar energy, thus reducing our CO2– carbon footprint.

Energy efficiency through modernization of plants and buildings

In addition, we also pay great attention to ecological measures in production. We also pay attention to energy efficiency when modernizing our plants and buildings, for example when installing the extraction system, which results in significant electricity savings.

Other notable examples that underscore our commitment to climate-neutral or environmentally friendly behavior are, on the one hand, the insulation of various buildings and, on the other hand, the acquisition of machinery, as a result of which we succeed in both reducing waste and saving dust emissions.

Furthermore, in 2019 we renewed both the heating burner and the air compressor, which is an example of the great importance we place at billerbeck on ensuring that our machines are state of the art and that we can not only work more efficiently but also save energy. To protect employees and the environment, our systems are also noise-reduced.

Environmentally friendly heating – Smart control of heating controllers

In order to ensure uniform temperatures In the offices, all heating controllers were replaced in 2022. Thanks to the latest technology and smart control of all radiators, energy savings of 30-40% per year are expected. An intelligent heat control system is used in the company buildings, in which all heaters are switched on automatically during core working hours with the help of a control function. In this way, we have already been avoiding unnecessary heating energy for years and have recorded important savings.

In addition, we strive for an ecological commitment in production. With the existing heat recovery system, we already save about 4 kg of heating oil per hour when drying the down and feathers, which corresponds to a reduction of about 6,000 to 8,000 kg of heating oil over the year. This means that with an annual consumption of 100,000 kg, we are recording savings of 7%.

Digitization

A printout here, a copy there – in a company like billerbeck, paper can be saved in many places. By reorganizing the printing of brochures, a significant reduction in paper was achieved. These are now printed in-house on environmentally friendly and sustainable paper. As an added value, this measure offers us a saving of resources and the avoidance of paper waste.

With the introduction of warehouse management software, on-time delivery can now be guaranteed. Due to the modern system, we can offer our employees more pleasant conditions as well as a significant improvement in the way they work. Another advantage is the optimization of the picking process.

Of course, we attach great importance to the further development of our work processes. We would like to further advance the digitalization of these processes in order to create a decisive technological basis that enables new ways of information and networking.

Conversion to LED lighting

In the billerbeck company buildings and in production, all lamps were replaced and converted to the latest energy-efficient LED technology. These provide optimal light for working – from the hall lighting to the desk.

In order to maintain full insurance coverage in the event of a fire, it was necessary to purchase new LED fluorescent lamps. The changeover in production presented us with particular challenges, as the LED light in the production halls has to be adjusted to daylight so that the different white tones of the textiles can be recognized.

Electric cars as company vehicles

When purchasing new company cars, we look for environmentally friendly alternatives such as electric cars. These can be charged at the company’s own charging station at any time.

Coffee vending machines without automatic plastic cup dispensers

Small sacrifices in everyday life – big benefits for the environment. At billerbeck, the beloved coffee from the coffee machine is now only available from the favorite cup. This saves a considerable amount of plastic waste in everyday life. Because even by making small sacrifices, every single employee can make a positive contribution to improving the environment every day.